The Importance of Arc Flash Awareness in the Electrical Industry

It is believed that electrocution was previously considered the number one cause of fatalities in the electrical industry. However, extensive research has revealed that arc flash incidents resulting in burns are, in fact, responsible for more casualties. Companies and organisations have taken proactive steps to continue to educate their employees and promote awareness of arc flash hazards in the workplace.

Among Australians, their level and knowledge and awareness about the dangers of arc flash vary depending on each worker's level of involvement and experience in the electrical industry. While some individuals may understand arc flash hazards well and the risks involved, others are still unfamiliar with this topic.

It is worth noting that the previous issue of AS/NZS 4836:2011, has helped raise awareness in Australia of the safety measures needed onsite to protect against arc flash incidents. The updated edition of AS/NZS 4836:2023 now includes significant changes that outline additional information on the selection and use of personal protective equipment regarding safe working on or near low-voltage and extra-low-voltage electrical installations and equipment.

What is an Arc Flash

When an electrical current travels through the air between two conductors or between a conductor and the ground, a sudden and potentially deadly release of energy occurs, creating an intense flash of light and heat, a loud noise, and a powerful wave of force, producing an arc flash. The result of an arc flash can cause significant damage to equipment and most importantly, severe injury and, at times, death to people in close proximity.

In order to prevent arc flash incidents, appropriate measures must be taken, such as using the correct personal protective equipment (PPE), assessing and maintaining electrical equipment to ensure they are in good working condition, and following safe work procedures and practices onsite consistently.

Changes involving the Selection & Use of Personal Protective Equipment

Personal protective equipment (PPE) under the AS/NZS 4836:2023 is determined per the risk assessment and the type of work being conducted. PPE is essential against arc flash because of its tendency to generate extreme heat and light that can cause severe burns, eye injuries, hearing loss, and physical and psychological trauma. The extreme temperatures caused by an arc flash can also ignite flammable materials, leading to more extensive fires and detonations.

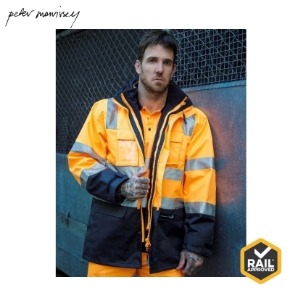

Generally, PPE used for arc flash protection includes flame-resistant clothing, gloves, face shields or spectacles, and protective footwear. These items can help protect workers from the dangers of arc flash by reducing their exposure to heat, flames and projectiles.

Section 11 of AS/NZS 4836:2023 states that "Protective clothing worn when working on or near exposed energised conductors or live conductive parts shall be appropriate for the purpose, fit correctly, cover the full body from wrist to ankle and be in working condition while the work is being performed." The standard shows an updated table regarding the PPE required, as well as a new table providing guidance on the selection of PPE for electrical risks. It is also noted that if an arc fault study has been carried out as part of a hazard identification and control process, this may supersede the guidance provided in the new Table 11.2 in Section 11 of the standard.

The Importance of Comprehensive Safety Measures

Although PPE is essential in the electrical industry, it is important to note that this is only one component against safe working on or near low-voltage and extra-low-voltage electrical installations and equipment. AS/NZS 4836:2023 specifies an extensive outline of safety procedures and requirements, including testing and maintenance of electrical equipment, safety signs and labels, requirements for electrical safety training and measures to prevent electric shock, electrical burns and other hazards. It aims to provide a framework for ensuring that taking steps and appropriate precautions can minimise arc flash risks and that employees can stay safe while working with electrical systems.

Need help selecting the right FR workwear and PPE? Contact Workwear Direct today for friendly expert advice, simple ordering and in house printing options all in one easy location. Servicing businesses for over 20 years, Australia wide.