Hand Protection is a crucial part of PPE for any physical labour task, handling dangerous chemicals, operating tools, equipment and machinery. It is imperative that appropriate ‘task-specific’ gloves, are worn in the workplace. The Graphex® range at Workwear Direct features an extended thumb and forefinger saddle. This beneficial design boosts the gloves’ overall protection, grip and longevity - further reducing the risk of hand injuries in the workplace.

For Work Health and Safety (WHS) Managers in Australia’s construction and mining industries, ensuring worker compliance with Personal Protective Equipment (PPE) is a daily challenge. Safe Work Australia reports that non-compliance contributes to 40% of workplace injuries, costing businesses millions in medical expenses and downtime. A critical pain point is lack of worker awareness about the importance of PPE, often due to inadequate training or skepticism about its effectiveness. The PPE Group’s brands—Force360, TRu Workwear, Graphex, and Bool PT—combine high-performance safety with comfort to make PPE indispensable, while our engaging toolbox talks reinforce awareness. Here’s how we help WHS Managers boost compliance and keep workers safe.

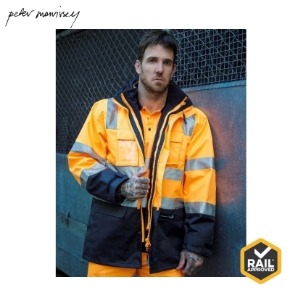

In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

In Australia’s construction and mining industries, ensuring workers wear Personal Protective Equipment (PPE) consistently is a constant challenge for Work Health and Safety (WHS) Managers. Non-compliance can lead to serious injuries, with Safe Work Australia reporting that up to 40% of workplace injuries are linked to improper or absent PPE use. One of the most significant pain points driving this issue is worker discomfort, which causes resistance to wearing PPE for long shifts in demanding environments. The PPE Group’s innovative brands—Force360, TRu Workwear, Graphex, and Bool PT—are designed to tackle this problem head-on by prioritising comfort without compromising safety.

Glove gauge is a crucial consideration that can impact everything from dexterity to cut protection. A higher gauge means more stitches per inch, resulting in lighter, more dense stitching. Take a closer look at the advantages of higher gauge cut gloves and why they might be the right choice for your industry or application.

Hand injuries are the most common type of work-related injuries among Australians. Therefore, gloves certified to the latest Australian and New Zealand standards provide employees and employers alike complete peace of mind, as the gloves supplied are of the highest quality and perform to their published mechanical performance claims.

Workers in the oil, gas, mining and construction industries become exposed daily to a diverse range of unforeseen circumstances and hazards, which can result in severe injury to their hands. In these environments, workers are at risk of crushing, puncturing, and pinching-related injuries. Hand injuries caused by impact hazards are painful, costly, and sometimes irreparable. It affects both employer and employee, making it crucial for all to understand the importance of wearing impact protection gloves, especially in industries with high risks of impact hazards.

Gauge your safety and performance! Understanding glove gauges is important for protecting your hands in the workplace. Gloves with specific gauges offer advantages and protection for certain tasks. For example, thinner gloves are perfect for electricians handling thin cables.

Most people in Australia are unaware of the process and importance of Certification vs Compliance; therefore, misconceptions occur, and consumers become exposed to the risk of workplace injury.