Force360 strive to offer a comprehensive range of safety eyewear that addresses the diverse needs of workers in various environments. Mirrored lenses are a standout choice within the product lineup, combining style with functional benefits that are particularly useful in certain work settings and leisure activities. Understanding when and why to use mirrored lenses can help you make an informed decision to enhance both your safety and comfort.

Hand Protection is a crucial part of PPE for any physical labour task, handling dangerous chemicals, operating tools, equipment and machinery. It is imperative that appropriate ‘task-specific’ gloves, are worn in the workplace. The Graphex® range at Workwear Direct features an extended thumb and forefinger saddle. This beneficial design boosts the gloves’ overall protection, grip and longevity - further reducing the risk of hand injuries in the workplace.

Gauge your safety and performance! Understanding glove gauges is important for protecting your hands in the workplace. Gloves with specific gauges offer advantages and protection for certain tasks. For example, thinner gloves are perfect for electricians handling thin cables. Deciding on the appropriate safety glove can be daunting due to the many available alternatives. The work environment and potential dangers should guide your choice. But first, what is gauge?

As sustainability becomes a core priority in Australia’s construction and mining industries, the demand for eco-friendly Personal Protective Equipment (PPE) is surging. According to the Australian Government’s National Waste Report published in 2024, the construction sector generates over 20 million tonnes of waste annually. The PPE Group is at the forefront of change, incorporating sustainable materials like recycled PET yarns in gloves, bio-based components in spectacles and goggles, plastic-free packaging with FSC-certified board, and durable designs that extend product life. Here’s how these innovations are transforming PPE while keeping workers safe onsite.

Certification vs Compliance Thursday, 25 September 2025 Unknown to most people, gloves in Australia are almost always sold as compliant to Australian or European Standards. They may show the ‘CE’ mark and mechanical score and symbol like ‘EN388 4542F’ . They may state in their literature ‘Compliant to European Standards’ or ‘meets European Standards’. They may also print AS/NZS 2161.3 on the glove as a way of claiming the glove is standards approved.

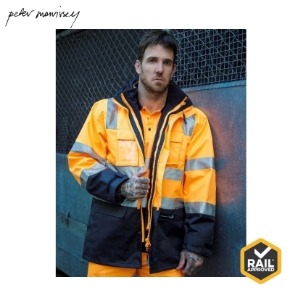

In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

The COVID-19 pandemic has sparked a surge in the use of respiratory masks, leading to an increased awareness of the importance of respiratory protection. With an array of respiratory masks available in the market, selecting the most appropriate type of respiratory protection can be challenging. Among these options are disposable and reusable respirators. Choosing the proper respiratory mask depends on several factors, such as intended use, comfort, durability, cost, environmental impact, and task-specific regulations and standards. The differences between disposable and reusable respirators, include their features, benefits, drawbacks, and environmental impact. It’s important to understand the differences between each respirator to help you make an informed decision when selecting the appropriate PPE.

Glove gauge is a crucial consideration that can impact everything from dexterity to cut protection. A higher gauge means more stitches per inch, resulting in lighter, more dense stitching. Take a closer look at the advantages of higher gauge cut gloves and why they might be the right choice for your industry or application.

Hand injuries are the most common type of work-related injuries among Australians. Therefore, gloves certified to the latest Australian and New Zealand standards provide employees and employers alike complete peace of mind, as the gloves supplied are of the highest quality and perform to their published mechanical performance claims.

Workers in the oil, gas, mining and construction industries become exposed daily to a diverse range of unforeseen circumstances and hazards, which can result in severe injury to their hands. In these environments, workers are at risk of crushing, puncturing, and pinching-related injuries. Hand injuries caused by impact hazards are painful, costly, and sometimes irreparable. It affects both employer and employee, making it crucial for all to understand the importance of wearing impact protection gloves, especially in industries with high risks of impact hazards.

Gauge your safety and performance! Understanding glove gauges is important for protecting your hands in the workplace. Gloves with specific gauges offer advantages and protection for certain tasks. For example, thinner gloves are perfect for electricians handling thin cables.

Most people in Australia are unaware of the process and importance of Certification vs Compliance; therefore, misconceptions occur, and consumers become exposed to the risk of workplace injury.