In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

In Australia’s construction and mining industries, ensuring workers wear Personal Protective Equipment (PPE) consistently is a constant challenge for Work Health and Safety (WHS) Managers. Non-compliance can lead to serious injuries, with Safe Work Australia reporting that up to 40% of workplace injuries are linked to improper or absent PPE use. One of the most significant pain points driving this issue is worker discomfort, which causes resistance to wearing PPE for long shifts in demanding environments. The PPE Group’s innovative brands—Force360, TRu Workwear, Graphex, and Bool PT—are designed to tackle this problem head-on by prioritising comfort without compromising safety.

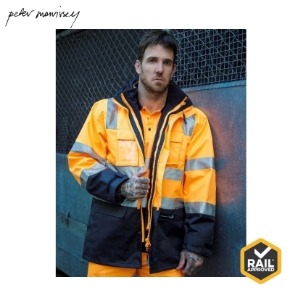

In the rugged terrains of the Australian mining and construction industries, where workers are often at the mercy of unpredictable weather, the quality of wet weather gear is not just about comfort—it's about safety and productivity. The backbone of ensuring the effectiveness of this critical gear is the Australian Standard AS 2001.2.17:1987, which provides a rigorous framework for testing the resistance of fabrics to water penetration. This blog explores how this standard applies to the mining and construction sectors and delves into the science behind the testing of wet weather garments.