As summer approaches, Australian workplaces face soaring temperatures and environmental challenges that impact both physical and mental health. For businesses, ensuring workplace safety becomes essential—not just for compliance but to foster staff wellbeing, productivity, and morale. Proactive preparation with appropriate workwear, health measures, and PPE solutions helps protect employees during the warmer months.

When choosing uniforms for your team, comfort, durability, and presentation are essential, but what about the fabric that brings it all together? The humble polo shirt has long been a staple of professional corporate wear. It’s versatile, easy to brand, and delivers a sharp, polished look across a variety of business environments. But not all polos are created equal. Behind every well-fitted garment is a fabric story worth knowing, because what your team wears really does matter.

Breathable garments allow air exchange between the wearer’s body and the environment. When a protective garment is breathable, the fabric or material provides air and moisture vapours. Breathability in protective garments is usually achieved through the use of certain fabric technologies or construction techniques that allow air molecules to pass through the material while having the ability to block larger liquid water droplets from penetrating the fabric. The garment can still provide protection while allowing heat and moisture to escape the body.

The process of applying tape patterns to workwear is crucial in ensuring that the tape is securely attached and remains visible during use. Tape patterns are applied to safety garments through various methods such as heat press, sewing and adhesive bonding.

Certification vs Compliance Thursday, 25 September 2025 Unknown to most people, gloves in Australia are almost always sold as compliant to Australian or European Standards. They may show the ‘CE’ mark and mechanical score and symbol like ‘EN388 4542F’ . They may state in their literature ‘Compliant to European Standards’ or ‘meets European Standards’. They may also print AS/NZS 2161.3 on the glove as a way of claiming the glove is standards approved.

For Work Health and Safety (WHS) Managers in Australia’s construction and mining industries, ensuring worker compliance with Personal Protective Equipment (PPE) is a daily challenge. Safe Work Australia reports that non-compliance contributes to 40% of workplace injuries, costing businesses millions in medical expenses and downtime. A critical pain point is lack of worker awareness about the importance of PPE, often due to inadequate training or skepticism about its effectiveness. The PPE Group’s brands—Force360, TRu Workwear, Graphex, and Bool PT—combine high-performance safety with comfort to make PPE indispensable, while our engaging toolbox talks reinforce awareness. Here’s how we help WHS Managers boost compliance and keep workers safe.

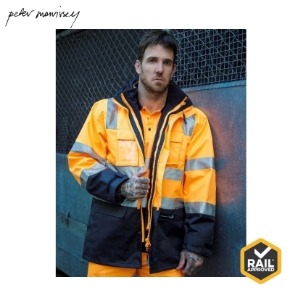

In the realm of industrial safety, high-visibility (hi-vis) garments are indispensable. However, maintaining their colour integrity and visibility is a challenge due to varying environmental conditions and the rigorous demands of industrial use. In this exploration, we'll delve into how different fibres like cotton and polyester withstand colour fading, the impacts of UV exposure, and the rigours of industrial washing.

With the introduction of the AS/NZS 1906.4:2023 standard, industrial workwear has seen an exciting expansion in colour options, including vibrant pinks and greens. This enhancement not only improves the visual appeal of safety garments but also emphasises the need for robust dyeing processes that ensure these colours withstand harsh industrial conditions. In this blog, we delve into vat dyeing and reactive dyeing, comparing their effectiveness in terms of longevity against industrial washing and UV exposure.

In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

In Australia’s construction and mining industries, ensuring workers wear Personal Protective Equipment (PPE) consistently is a constant challenge for Work Health and Safety (WHS) Managers. Non-compliance can lead to serious injuries, with Safe Work Australia reporting that up to 40% of workplace injuries are linked to improper or absent PPE use. One of the most significant pain points driving this issue is worker discomfort, which causes resistance to wearing PPE for long shifts in demanding environments. The PPE Group’s innovative brands—Force360, TRu Workwear, Graphex, and Bool PT—are designed to tackle this problem head-on by prioritising comfort without compromising safety.

In today’s competitive business landscape, presentation isn’t just important — it’s a direct reflection of your brand. From corporate offices and healthcare clinics to fast-paced hospitality venues, what your team wears matters. At Workwear Direct, we proudly supply leading Australian businesses with uniforms that blend style, comfort, and performance — and when it comes to trusted brands, Biz Collection stands out as one of the best.

It is a fact that too much noise onsite can lead to temporary or permanent hearing loss or tinnitus – defined by ringing in the ears. The most at risk category of workers is industrial manufacturing workers who rely on their PPE to protect them from Noise-Induced Hearing Loss (NIHL). NIHL can be brought upon by long-term exposure to harmful levels of sounds. With Force360 certified hearing protection you are guaranteed protection for the stipulated dB classification, as tested to Australian standards. However, as we know there are more factors at play when preventing a team from hearing injuries. How effective is hearing protection is being used?