Certification vs Compliance Thursday, 25 September 2025 Unknown to most people, gloves in Australia are almost always sold as compliant to Australian or European Standards. They may show the ‘CE’ mark and mechanical score and symbol like ‘EN388 4542F’ . They may state in their literature ‘Compliant to European Standards’ or ‘meets European Standards’. They may also print AS/NZS 2161.3 on the glove as a way of claiming the glove is standards approved.

For Work Health and Safety (WHS) Managers in Australia’s construction and mining industries, ensuring worker compliance with Personal Protective Equipment (PPE) is a daily challenge. Safe Work Australia reports that non-compliance contributes to 40% of workplace injuries, costing businesses millions in medical expenses and downtime. A critical pain point is lack of worker awareness about the importance of PPE, often due to inadequate training or skepticism about its effectiveness. The PPE Group’s brands—Force360, TRu Workwear, Graphex, and Bool PT—combine high-performance safety with comfort to make PPE indispensable, while our engaging toolbox talks reinforce awareness. Here’s how we help WHS Managers boost compliance and keep workers safe.

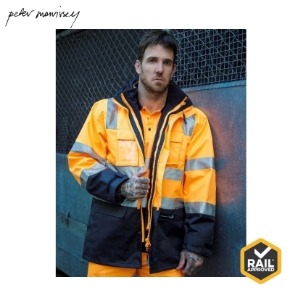

In the realm of industrial safety, high-visibility (hi-vis) garments are indispensable. However, maintaining their colour integrity and visibility is a challenge due to varying environmental conditions and the rigorous demands of industrial use. In this exploration, we'll delve into how different fibres like cotton and polyester withstand colour fading, the impacts of UV exposure, and the rigours of industrial washing.

With the introduction of the AS/NZS 1906.4:2023 standard, industrial workwear has seen an exciting expansion in colour options, including vibrant pinks and greens. This enhancement not only improves the visual appeal of safety garments but also emphasises the need for robust dyeing processes that ensure these colours withstand harsh industrial conditions. In this blog, we delve into vat dyeing and reactive dyeing, comparing their effectiveness in terms of longevity against industrial washing and UV exposure.

In Australia’s high-risk mining and construction industries, personal protective equipment (PPE) is more than just gear - it’s a lifeline. Despite stringent safety regulations, non-compliance with PPE usage remains a persistent issue, leading to lost time injuries (LTIs), operational disruptions, and significant financial burdens. At Private Brands, we understand the critical role our certified PPE and workwear ranges, including Force360, Graphex, Bool PT FR workwear, and TRu Workwear high-visibility workwear, plays in preventing these costly consequences. Let’s explore the true cost of not wearing PPE, the impact on subcontractors, and why investing in quality PPE is a game-changer for both business and worker safety.

In Australia’s construction and mining industries, ensuring workers wear Personal Protective Equipment (PPE) consistently is a constant challenge for Work Health and Safety (WHS) Managers. Non-compliance can lead to serious injuries, with Safe Work Australia reporting that up to 40% of workplace injuries are linked to improper or absent PPE use. One of the most significant pain points driving this issue is worker discomfort, which causes resistance to wearing PPE for long shifts in demanding environments. The PPE Group’s innovative brands—Force360, TRu Workwear, Graphex, and Bool PT—are designed to tackle this problem head-on by prioritising comfort without compromising safety.

It is a fact that too much noise onsite can lead to temporary or permanent hearing loss or tinnitus – defined by ringing in the ears. The most at risk category of workers is industrial manufacturing workers who rely on their PPE to protect them from Noise-Induced Hearing Loss (NIHL). NIHL can be brought upon by long-term exposure to harmful levels of sounds. With Force360 certified hearing protection you are guaranteed protection for the stipulated dB classification, as tested to Australian standards. However, as we know there are more factors at play when preventing a team from hearing injuries. How effective is hearing protection is being used?

The purpose of a respirator is to protect the user from inhaling airborne particles. Proper fitment is essential for a respirator to protect the user from airborne particles, fumes, viruses, bacteria and other hazardous substances. An airtight seal ensures that air passing through the respirator is filtered, removing pollutants before they are breathed in. If there are gaps or obstructions between the respirator and the face, contaminated air can bypass the filter, exposing the user to potentially hazardous particles that may enter their respiratory system.

The COVID-19 pandemic has sparked a surge in the use of respiratory masks, leading to an increased awareness of the importance of respiratory protection. With an array of respiratory masks available in the market, selecting the most appropriate type of respiratory protection can be challenging. Among these options are disposable and reusable respirators. Choosing the proper respiratory mask depends on several factors, such as intended use, comfort, durability, cost, environmental impact, and task-specific regulations and standards. The differences between disposable and reusable respirators, include their features, benefits, drawbacks, and environmental impact. It’s important to understand the differences between each respirator to help you make an informed decision when selecting the appropriate PPE.

Excessive occupational noise is a common risk in workplaces with noisy tools and machinery, and around truck and forklift traffic. Exposure to loud noises, such as jackhammers, jet engines, firearms and many others, can put workers at risk. Damage to our hearing is irreparable, resulting in slight or complete hearing loss. Still, it is preventable if the appropriate hearing protection is used. Choosing the proper hearing protection, whether disposable, reusable, detachable or customised, is critical because when fitted and used correctly, efficacy is maximised and dangerous noise levels are reduced.

Hearing loss frequently happens due to exposure to loud environments. It can result from a singular loud noise such as an explosion of a firecracker near your ear, or more often, it can result over time from repeated exposure to loud sounds causing damage to our ears. Our ears are incredibly versatile and an essential organ in our bodies. Hence, we measure sound levels, which can assist us in understanding what things and settings can potentially harm our ears.

Discover essential boot cleaning & foot care tips for cold weather. Keep feet warm & safe. Quality boots & maintenance advice. Stay prepared.