The purpose of a respirator is to protect the user from inhaling airborne particles. Proper fitment is essential for a respirator to protect the user from airborne particles, fumes, viruses, bacteria and other hazardous substances. An airtight seal ensures that air passing through the respirator is filtered, removing pollutants before they are breathed in. If there are gaps or obstructions between the respirator and the face, contaminated air can bypass the filter, exposing the user to potentially hazardous particles that may enter their respiratory system.

The COVID-19 pandemic has sparked a surge in the use of respiratory masks, leading to an increased awareness of the importance of respiratory protection. With an array of respiratory masks available in the market, selecting the most appropriate type of respiratory protection can be challenging. Among these options are disposable and reusable respirators. Choosing the proper respiratory mask depends on several factors, such as intended use, comfort, durability, cost, environmental impact, and task-specific regulations and standards. The differences between disposable and reusable respirators, include their features, benefits, drawbacks, and environmental impact. It’s important to understand the differences between each respirator to help you make an informed decision when selecting the appropriate PPE.

Excessive occupational noise is a common risk in workplaces with noisy tools and machinery, and around truck and forklift traffic. Exposure to loud noises, such as jackhammers, jet engines, firearms and many others, can put workers at risk. Damage to our hearing is irreparable, resulting in slight or complete hearing loss. Still, it is preventable if the appropriate hearing protection is used. Choosing the proper hearing protection, whether disposable, reusable, detachable or customised, is critical because when fitted and used correctly, efficacy is maximised and dangerous noise levels are reduced.

Hearing loss frequently happens due to exposure to loud environments. It can result from a singular loud noise such as an explosion of a firecracker near your ear, or more often, it can result over time from repeated exposure to loud sounds causing damage to our ears. Our ears are incredibly versatile and an essential organ in our bodies. Hence, we measure sound levels, which can assist us in understanding what things and settings can potentially harm our ears.

Discover essential boot cleaning & foot care tips for cold weather. Keep feet warm & safe. Quality boots & maintenance advice. Stay prepared.

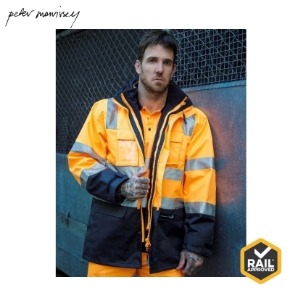

In the realm of industrial safety, one aspect holds paramount importance: Personal Protective Equipment (PPE). Serving as a crucial line of defense, PPE plays a significant role in safeguarding workers against potential hazards. This comprehensive guide aims to shed light on the significance of PPE in industrial safety and its various applications. At Workwear Direct, Australia's trusted provider of Workwear & Safety solutions, we recognize the importance of PPE and offer a wide range of high-quality products to ensure the safety of your workforce.

Discover tips for stylish winter corporate wear. Layering, materials, and accessories. Stay warm and professional with Corporate Wear Direct.

Glove gauge is a crucial consideration that can impact everything from dexterity to cut protection. A higher gauge means more stitches per inch, resulting in lighter, more dense stitching. Take a closer look at the advantages of higher gauge cut gloves and why they might be the right choice for your industry or application.

Hand injuries are the most common type of work-related injuries among Australians. Therefore, gloves certified to the latest Australian and New Zealand standards provide employees and employers alike complete peace of mind, as the gloves supplied are of the highest quality and perform to their published mechanical performance claims.

Workers in the oil, gas, mining and construction industries become exposed daily to a diverse range of unforeseen circumstances and hazards, which can result in severe injury to their hands. In these environments, workers are at risk of crushing, puncturing, and pinching-related injuries. Hand injuries caused by impact hazards are painful, costly, and sometimes irreparable. It affects both employer and employee, making it crucial for all to understand the importance of wearing impact protection gloves, especially in industries with high risks of impact hazards.

Gauge your safety and performance! Understanding glove gauges is important for protecting your hands in the workplace. Gloves with specific gauges offer advantages and protection for certain tasks. For example, thinner gloves are perfect for electricians handling thin cables.

Most people in Australia are unaware of the process and importance of Certification vs Compliance; therefore, misconceptions occur, and consumers become exposed to the risk of workplace injury.